An arc welding robot is a mechanical device that uses electricity to create an arc of light between two metal pieces. This arc melts the metals, which join together to create a weld. Arc welding robots are widely used in manufacturing and can be programmed to weld specific shapes and patterns. While they may seem complex, arc welding robots are simple machines anyone can operate with little training.

What is an arc welding robot, and what does it do?

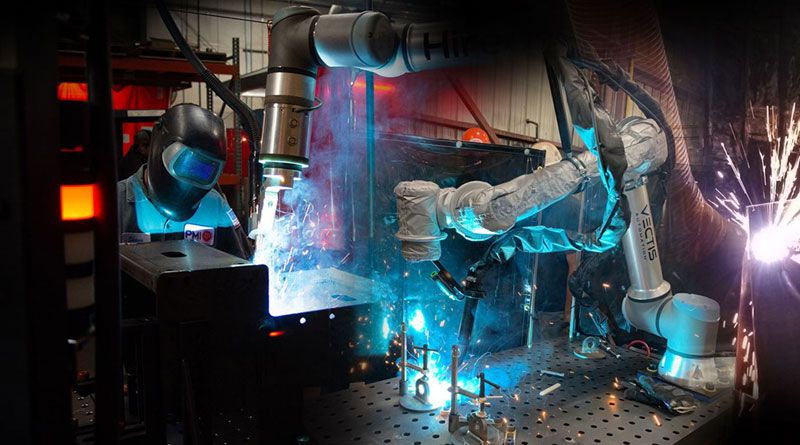

An arc welding robot is a mechanical device programmed to weld two pieces of metal together using electricity. A power supply sends an electric current to the robot, creating an arc of light between the two metal pieces. This arc melts both metals and creates a strong joint known as a weld. The robots are used mainly in manufacturing but can also be used for other welding projects, such as automotive repairs and metal fabrication.

The robot is controlled by a computer program that can be programmed to create specific shapes, patterns, and welds. The robots are usually equipped with sensors that allow them to make precise adjustments in their position or speed during operation. It ensures that the finished product meets the desired specifications.

What are the components of an arc welding robot?

An arc welding robot comprises several essential parts, each of which plays a crucial role in the operation of the machine. The power supply sends electricity to the robot, which it then uses to create an arc between two pieces of metal. The robotic arm is a moveable arm that holds the welding torch in place and moves it to where the weld is required. Sensors are also installed on the robot to gauge its position or speed during operation.

The power supply of an arc welding robot can vary depending on its size and application. In industrial settings, high-powered generators may be used to power the robot. For smaller projects, a standard plug-in can be used.

What are the benefits of using an arc welding robot over traditional welding methods?

Traditional welding methods, such as stick welding, require a skilled welder to create a weld. Arc welding robots can do the same job with greater accuracy and faster speeds than humans. It makes them ideal for mass production tasks where precision is vital.

Additionally, arc welding robots can be programmed to perform complex welding tasks that would be difficult or impossible for humans. It makes them ideal for challenging projects that require intricate welds and patterns.

Are there any disadvantages to using an arc welding robot instead of a human welder?

The most obvious disadvantage of using an arc welding robot is the cost. Industrial robots can be expensive and require maintenance and repairs over time.

Additionally, large welding robots usually need help to handle complex or intricate welds that a skilled human welder could create.

Finally, since the robots are programmed via computer software, there is potential for errors in programming that could lead to welding mistakes.

Despite all of this, you may be relieved to discover that anyone can mitigate these issues with the use of a smaller robot arm or a cobot – collaborative robot. Cobots have smart integration and can be programmed and reprogrammed, increasing flexibility in the welding process. They also come equipped with spatial sensors to ensure they do the job right, and they can be fitted with intricate end effectors for more complex welds.

How to choose the right arc-welding robot for your needs?

The first step in choosing the right arc welding robot for your project is determining the size and power requirements. Different robots can handle different amounts of electricity, so it’s essential to make sure you choose one with enough capacity to handle your particular application.

Additionally, consider how complex the welds need to be and if additional sensors or arms are required. Finally, consider your budget and ensure that you select a robot that fits within it.

Conclusion

An arc welding robot is invaluable in manufacturing settings where precision and speed are essential. These robots offer numerous advantages over traditional welding methods, such as greater accuracy, faster speeds, and affordability. While they may seem intimidating, anyone can learn how to operate and maintain an arc-welding robot with practice.

With suitable machines and programming, these robots can create intricate welds and patterns that would be impossible for a human welder. So, an arc welding robot may be the perfect solution if you’re looking to streamline your welding tasks.

Namaste UI collaborates closely with clients to develop tailored guest posting strategies that align with their unique goals and target audiences. Their commitment to delivering high-quality, niche-specific content ensures that each guest post not only meets but exceeds the expectations of both clients and the hosting platforms. Connect with us on social media for the latest updates on guest posting trends, outreach strategies, and digital marketing tips. For any types of guest posting services, contact us on info[at]namasteui.com.